HEAT UP CCTV FURNACE VIEWING SYSTEM

Closed Circuit Television Systems are now becoming very popular and a powerful tool for the modern Furnace Manager.

Modern Cameras are more compact and of better reliability and quality than ever before. This enables our design teams at HEAT UP to produce systems which are specifically designed for the Glass Furnace environment.

Why should you consider a HEAT UP CCTV system for your furnace?

The answers are many fold and once you've had the HEAT UP CCTV system installed you'll wonder how you managed without one for all those years.

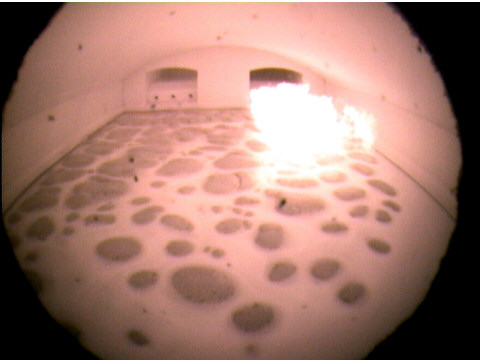

You will be surprised just how much of the interior of the furnace is visible with the 110 degree field of view from the HEAT UP lens system. When the Camera is correctly positioned you will be able to watch flame patterns, burner reversals, batch pile formation, batch pile patterns and melting rates with much more clarity and accuracy than through a multitude of site holes and all from the control room. This also means that with a multi furnace operation all furnaces can be seen from a central point.

When the system is linked to a Video Cassette Recorder you will be able to hold records of past furnace operation which you can use to look back on when a production problem is noticed hours or days later. When the Time Lapse VCR is used the speeded up recording enables batch patterns to be observed as never before possible, watching an individual pile in its journey from the charger to its final melting. To review the previous days melting the Furnace, Production and Factory Managers can watch the full 24 hours in as little as 5 to 10 minutes.

The HEAT UP CCTV system consists of four main parts, the Camera system, the Retraction system, the Electrical panel, the Monitor and VCR. From the initial concept simplicity, endurance and ease of maintenance have been the prerequisites of the HEAT UP CCTV design.

NO water cooling is used with the HEAT UP CCTV, only air. This negates the need for water flow and return pipework, softeners or coolers.

The same air used for cooling is used for the retraction system. Only one 1" air supply is needed to the HEAT UP CCTV system. This can be factory or instrument air, we supply regulator/filter/oil and water separators and require only 1scmm/35scfm at 4bar/60psi into our system.

Because we use no water cooling we have designed the through wall lens tube to be much smaller than conventional systems this allows us to require only a 25mm/1" hole in the furnace wall and no special wall block, in most cases the hole can be drill while in production and the HEAT UP CCTV installed on the run.

The air supply is monitored by a pressure switch in the Camera housing itself after the ONE flexible hose so that a failure of air supply or the hose is definitely registered at the important point, the Camera and Lens assemblies. This will immediately engage the Retraction mechanism to withdraw the Lens tube from the furnace, as will a power failure.

In the event of an air failure there is an air reservoir built into the Retraction steelwork sufficient to retract the Camera. The complete pipework to the retraction system is in steel or copper so that there is never a risk of pipework failure to the retraction cylinder.

The Electrical panel can be run from 110 or 240 vac. but the camera and retraction solenoid valve are both 12vdc. so that no dangerous voltages are used in the hot area on the furnace and all materials, as far as are available, such as the flexible air hose, retraction cylinder and cables are all of high temperature specification

In all the HEAT UP CCTV parts selection priority has been given to the best regardless of cost as we believe that in the long term THE BEST COSTS LESS.

The system comes with a comprehensive installation kit and can be customer installed or one of our engineers contracted for the HEAT UP installation service which includes the full installation except for the drilling of the hole in the furnace wall.

Because of the designed simplicity of the system it does not take an electronics, pneumatics or optics engineer to understand the HEAT UP CCTV System. This means that your furnace operators and regular maintenance staff will be immediately comfortable with the equipment and feel able and willing to look after the system and so they will not allow things to fall into disrepair because to fix something will be easy and quick to do, this will give you less down time of the equipment and less maintenance costs for your HEAT UP CCTV System.

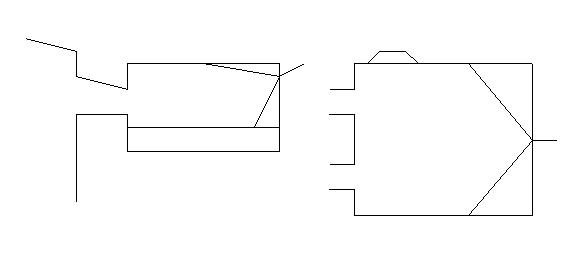

Side view of Furnace

Plan view of Furnace